MARITECHS optimizes hull lines by the method of parametric modeling combined with CFD calculation. It is the best state-of-the-art method used by the top design companies, shipyards and class societies. With this method, it is possible to reduce the required power of the main engine by 3-10% depending on the type of ship.

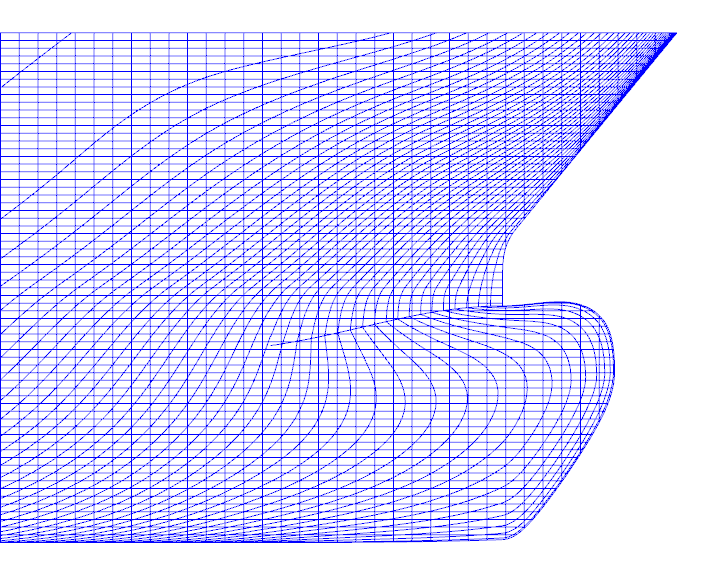

To optimize the hull lines, the first step is to build the train line using curves, parametric curved surfaces. Then to change the shape of the hull, we just need to change the values of the parameters. Depending on optimizing cases, we will build parametric hull for one region or the whole ship.

Normally, a linear optimization problem will go through the following parts:

- Optimized hull lines of after region, forward region and parallel body .

- Optimizing bulbus bow.

For each optimizing region, we will use different objective functions. For after region we will use the objective function such as the minimum power. For tube body region and forward region, the objective function will be minimum resistance.

The optimization process will be fully automated, meaning the hull lines automatically will be generated and transferred to the CFD software for calculation. Thus, human errors will be avoided, and computation time will be greatly shortened for a very large number of cases.

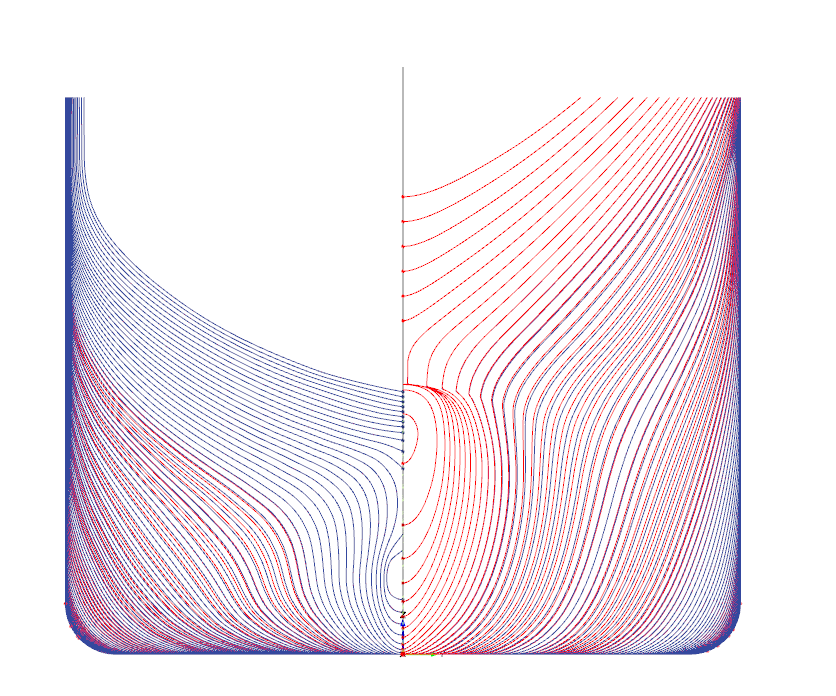

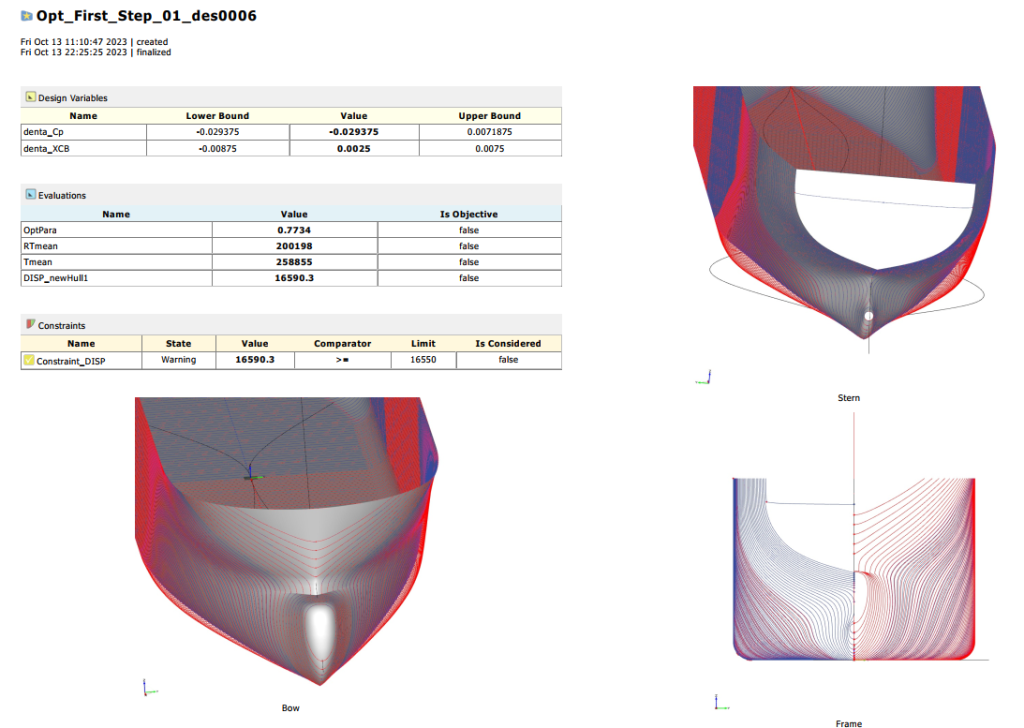

Frame section and SAC curve of original hull (red color) and modified hull (blue color)

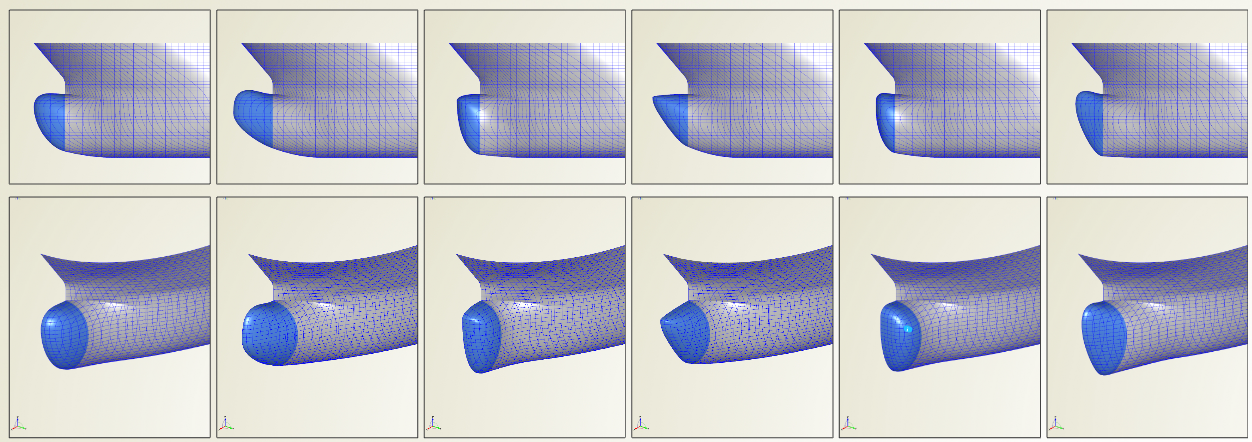

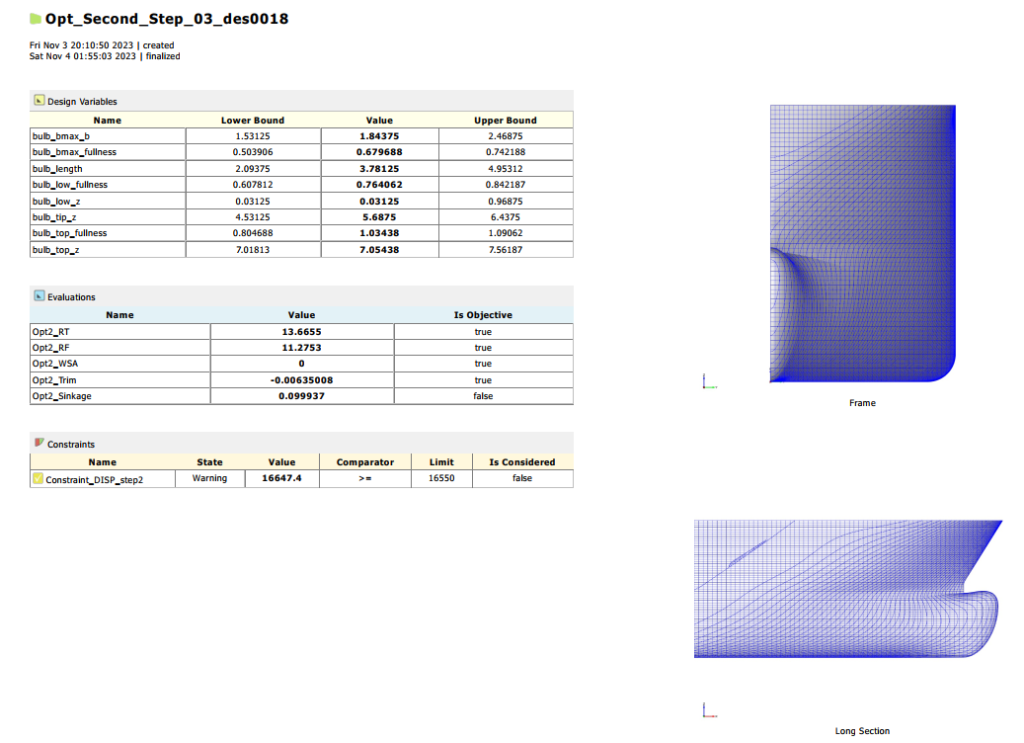

Parametric hull for bulbus bow

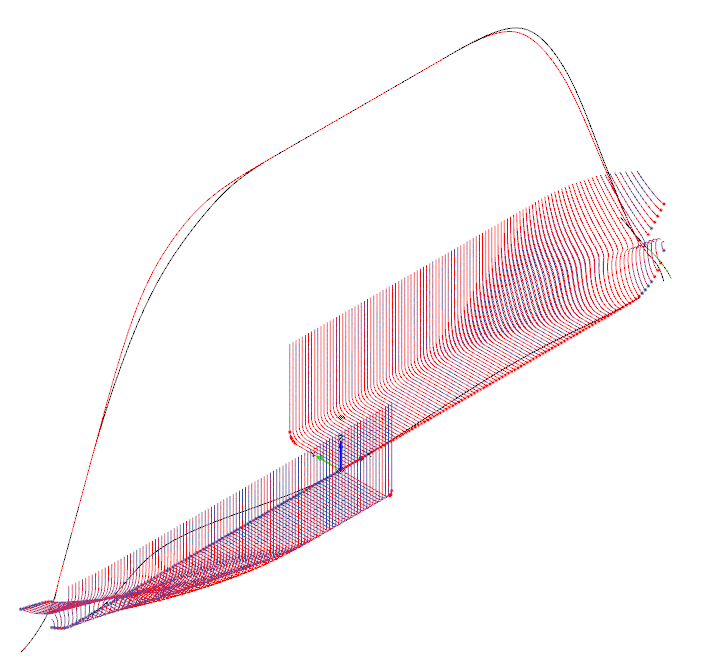

Optimizing result for parallel body, entrance region, run region

Optimizing result for bulbus bow

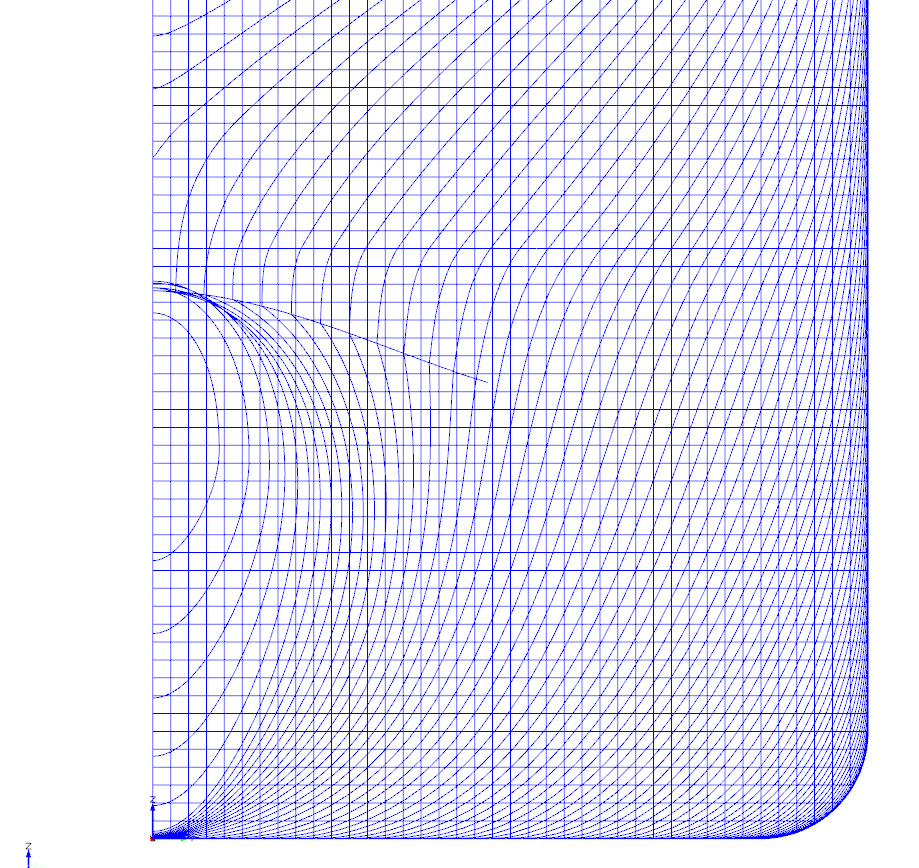

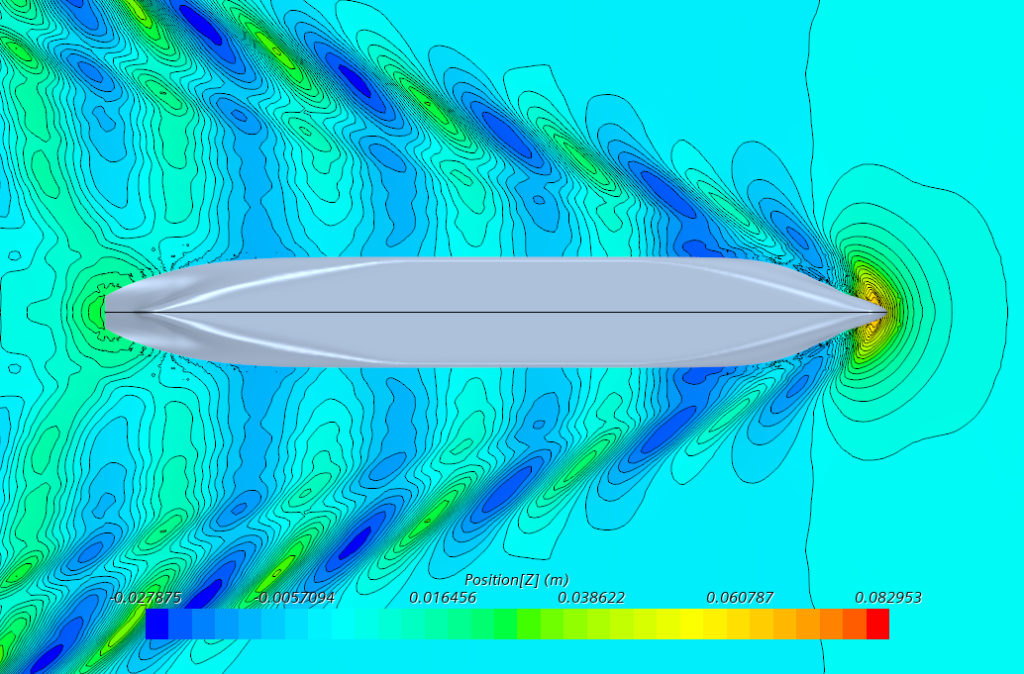

wave system for optimizing cases

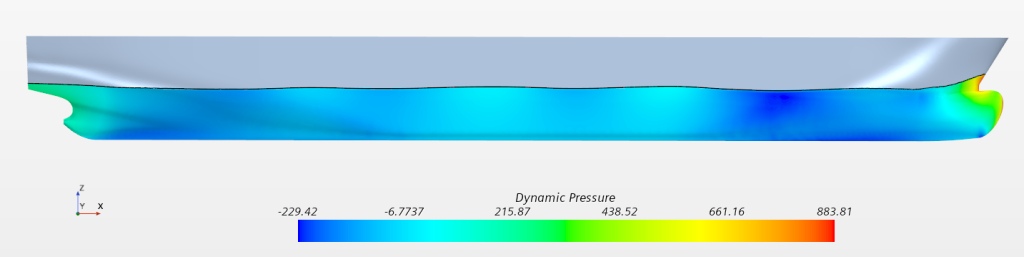

Dynamic pressure distribution for optimizing cases